The remanufacturing process

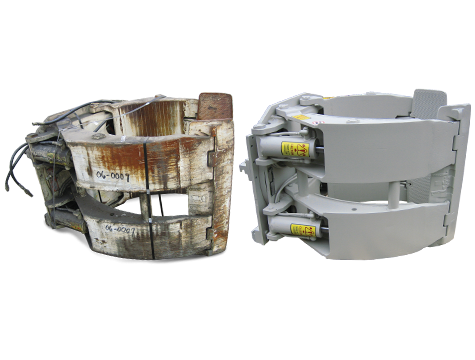

Before the Cascade nameplate goes on any remanufactured attachment, you can be sure it’s been through the most rigorous remanufacturing process in the industry. It begins with the inspection of a used Cascade attachment to see that it is a candidate for remanufacture. Each attachment then goes through the following steps:

Steam cleaning. All oil, grease and dirt is removed.

Disassembly. Every attachment is completely disassembled, steam cleaned again and inspected.

Shotblasting. Component parts are cleaned to bare metal.

Magnufluxing. Every weld is carefully inspected to reveal possible defects invisible to the naked eye.

Repairs and remanufacturing. Parts are repaired or replaced to meet all factory specifications.

Hydraulics. All hoses are replaced. Cylinders and valves are remanufactured and tested.

Reassembly and testing. All components are reassembled, tested and checked for conformance to Cascade engineering standards.

Painting. Each unit receives a coat of paint that serves either as a final color or as a base primer for your own color preference.

Re-Bonding

Do your contact pads need a make-over? Is the rubber worn off the corners, cracked or peeling?

If the existing aluminum plate is in working condition, Cascade certified re-bonding is the perfect solution.