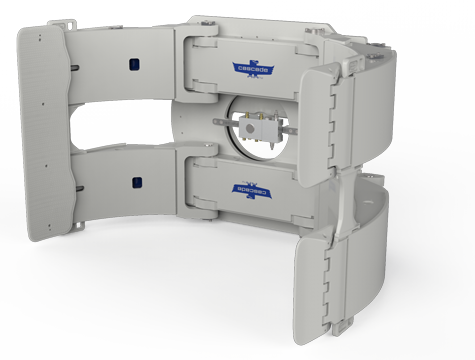

- Highly durable arm structure and pad profile that eliminates damage from knifing between rolls in containers, trailers, and railcars

- Pad protectors reduce wear to the contact pads

- Pad alignment system using dual spring technology holds the contact pads in proper alignment

- A variety of arm styles for flexibility in any application

- Short arm positioning to optimize small roll handling

- Excellent visibility through arms

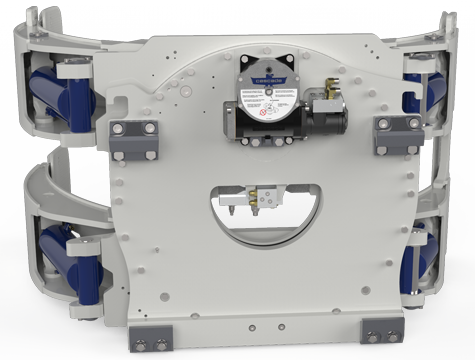

- High-flow revolving connection provides fast arm speed and less energy consumption

- Quick 360º rotation speed with 15-tooth pinion

- High-torque, heavy-duty rotator drivetrain proven to provide superior durability

- 55H: High-torque, heavy-duty dual rotator drivetrain for fast, continuous rotation

- Can be configured with 2, 3 or 4 pads

- High-strength castings provide structural life needed for robust applications

- Wide range of contact pads for every type of paper

- Split or solid arm

- Fixed short arm for applications with roll sizes on the high side of the clamp's capacity range

- 180° Stop Group

- 55H: Low torque, heavy-duty single-drive rotator drivetrain

- AFC - Adaptive Force Control

- HFC - Hydraulic Force Control

- ERC - Electronic Rotational Control

- Drop Stop System

- HFC with Drop Stop